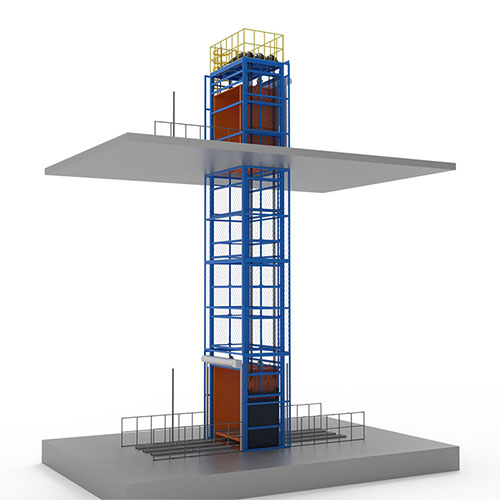

Vertical Reciprocating Conveyors with Roller Conveyor

The roller-type vertical reciprocating conveyor (VRC) realizes unmanned operation and full intelligent operation. It is a safe and economical way to lift and lower materials in factories, warehouses, distribution facilities, industrial plants, institutions or anywhere products or supplies need to be moved from one floor to another.

Material lift vertical reciprocating conveyor provides fast, efficient and convenient access to mezzanines, balconies, basements and between floors of multi-story buildings. The main components of VRC include guide columns, brackets and mechanical or hydraulic actuators. It adopts cold-forged steel structure, which has a strong structure, simple maintenance, high reliability, and can be fully automatic, saving manpower, and has obvious advantages and uses in various industrial scenarios. Realize multi-layer conveying; a variety of conveying options, suitable for different needs; variable frequency electrical control, stable and reliable operation.

This product is a non-standard customized lift. Please contact our customer service to provide production purposes and equipment parameters so that we can provide you with a quotation plan.

With our extensive design experience and knowledge, we are able to provide high-quality and durable lifting solutions that can meet the demanding requirements of this application and environment.

For more information, please call: 400-666-0979

1. Safety inspection at the entrance

Infrared grating technology is used in many places for real-time detection, automatic shutdown or deceleration, flexibility and customization to adapt to different safety needs

2. Intelligent monitoring system

Real-time tracking of the operating status of the elevator, monitoring of load, height, and speed to ensure visualization and real-time control of the operation process

3. Intelligent control system

Adopt digital and automated means to automatically perform the lifting and stopping of the elevator, reduce manual intervention, improve production efficiency and reduce energy consumption, and comply with energy conservation and environmental protection

4. Automatic docking of import and export bodies

In the automated production line, the seamless connection of the conveyor line can be used to improve production efficiency. The warehouse freight elevator can be equipped with a cache area at the entrance and exit to improve logistics efficiency and reduce waiting time

5. Simple operation

Adopting touch screen design, intelligent conveying unmanned high operation mode, materials can be conveyed upwards or downwards

6. Maximum conveying capacity

It can reach more than 90 pallets per hour, and the maximum conveying speed is 90 meters per minute

7. Small footprint

It has the advantages of small footprint, high conveying efficiency, long conveying distance, large transport volume, and continuous conveying